Drive, turn, and stop.

These are critical safety components that take control of stable maneuverability of an automobile as well as ride comfort.

This component supports the engine, suspension, steering wheel, etc., and plays a role in absorbing shocks from the road surface and energy of collision impacts. It suppresses torsion of the vehicle body during driving, and improves ride comfort and driving stability.

We have achieved our products' weight saving in compliance with the strict impact performance requirements even in the limited space by devising the optimum structures and shapes.

This component supports and connects the undercarriage and drive system parts on the rear with the vehicle body. The main role of this components is to determine the tire positions and to absorb shocks from the road surface.

We have devised designing of Rear Suspension Crossmember, in which the link configuration is focused on for significantly improving wheels' support stiffness. We also have the production lines, in which the materials with same shape but different thickness can be weld-assembled with a single jig.

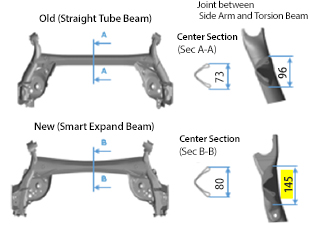

This component is composed of a beam, and left and right arms connecting the body and the tires. It is designed to tolerate the torsion necessary for driving, and it absorbs shocks from the road surface. It has fewer parts compared to other types of suspensions, and therefore it is lighter in weight and more cost effective. Another advantage, among other things, is that it can preserve more space for the fuel tank and cargo space.

The beam is changed from the conventional U-shaped sheet metal type to the "crushed tube" type, in which the pipe is crushed. It satisfies the required performance despite its thin property and small cross-section, contributing to weight reduction of approximately 20%.

Our unique tube forming technology, which makes the perimeter variable, can significantly improve the bending stiffness with maintaining the torsional stiffness. By expanding both ends of the tube, we can reinforce the roll stiffness and the toe stiffness which are indispensable for the vehicle motion performance.

The main role of this component is to determine the tire positions and angles, support the input from the road surface, and to hold necessary functional components.

Components that are conventionally manufactured by means of forging and casting are optimized by sheet metal structure using high‐tensile materials to reduce weight and cost while increasing strength.

Copyright(C) Y-TEC CORPORATION All Rights Reserved.