Certified Ergonomist

Are you familiar with the study of ergonomics? Ergonomics is "a science for designing and improving machineries, tools, and environment, etc. to facilitate the use for human workers." Y-tec intends to create productions lines and workplaces that are human friendly, regardless of the worker's age or sex, and commits itself in making continuous improvements. Our improvement activities based on ergonomics are paid off and we have acquired certifications from Japan Ergonomics Society such as the Certified Associate Ergonomics Professional and Certified Ergonomics Assistant.

While paying attention to psychological conditions of our workers in addition to their physical conditions, we conduct a number of investigations and improvements for the purpose of creating the most human-friendly production lines in Japan.

- However we were accustomed to the works we do on daily basis, after knowing that some of such works were not appropriate from the view of ergonomics, we are now able to perceive physical and psychological burdens that we were previously unaware of.

- Improvements on working posture, handling of heavy objects, and working environment including lighting and noise have made our work easier overall, and we are not as tired as before. In addition, we can complete the same amount of work in a shorter time frame.

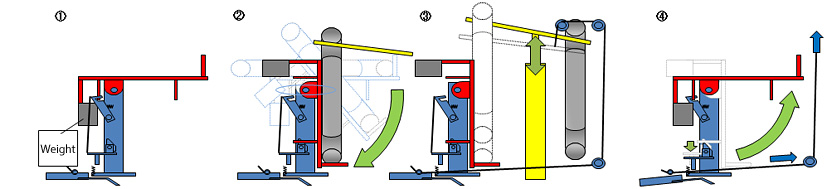

There was much burden on the worker and a possible safety risk in the work of pulling out a product from a jig and hanging it on a cooling buffer. As the cooling buffer was located too far from the jig, there was a plan to bring the inlet nearer. However, by doing so, it would reduce the space for reversing. This raises a concern of increase in work burden.

The worker no longer needs to turn the product vertically. It is now put onto the table of the machine as it was unloaded from the jig, and its own weight turns itself into the hanging position. When the product is moved into the cooling buffer, the lock is released by the movement of the cooling buffer, and the table of the machine returns to the horizontal position by the weight.

Copyright(C) Y-TEC CORPORATION All Rights Reserved.